Report on the Integrated Development of Battery Testing Technology and AC/DC Bidirectional Converter Technology

2025-06-12

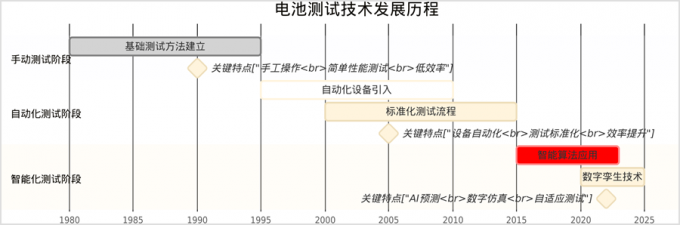

The development history of battery testing technology

Battery testing technology has gone through three major development stages: manual testing, automated testing, and intelligent testing. Each stage represents a significant leap in technology and methodology.

The technological evolution from manual to intelligent

Early battery testing mainly relied on manual operation, and technicians needed to manually record and analyze data. The characteristics of this stage are:

The testing process is highly dependent on manual operation and monitoring

The efficiency of data collection and analysis is low

The test results are susceptible to human factors

It is difficult to conduct long-term or large-scale tests

With the development of computer technology, battery testing entered the automation stage (from the 1990s to the 2010s). The main characteristics of this period include:

Introduce a computer control system to achieve the automation of the testing process

Develop dedicated battery testing equipment and software

Establish standardized testing methods and procedures

The accuracy and repeatability of the test have been improved

The progress at this stage has significantly enhanced the efficiency of battery testing, providing strong support for the rapid development of battery technology. The automated test system is capable of performing complex charge and discharge cycle tests and automatically recording and analyzing data [8].

At present, battery testing technology has entered the intelligent stage (from the 2020s to the present), and its main features are:

Apply artificial intelligence and big data technologies to predict battery performance and assess battery life

Develop non-destructive testing technology and micro-nano testing technology to improve testing accuracy

Achieve a close integration of testing with battery design, manufacturing, recycling and other links

• Emphasize full life cycle testing [8]

At this stage, machine learning algorithms are widely applied in the prediction of battery cycle life. Studies show that traditional machine learning algorithms perform exceptionally well when dealing with limited data. For instance, random forest regressors can achieve an average absolute percentage error of at least 9.8% [4].

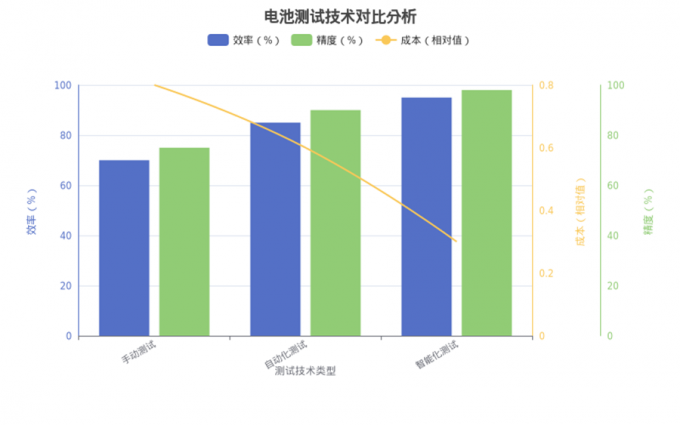

Comparison of efficiency, accuracy and cost in the three stages

Battery testing techniques at different stages have significant differences in terms of efficiency, accuracy and cost:

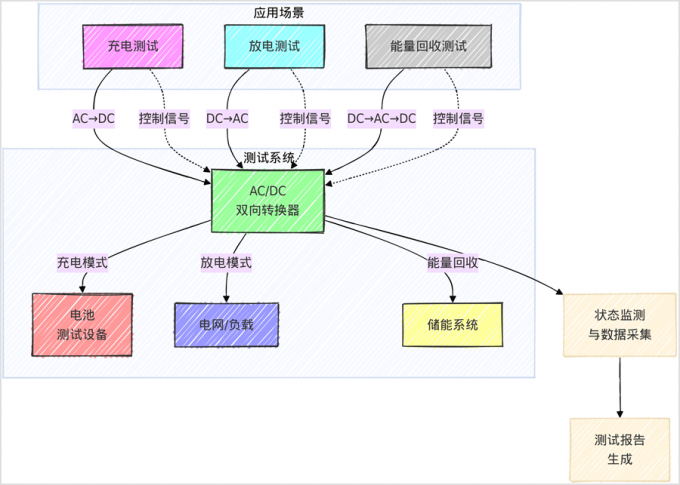

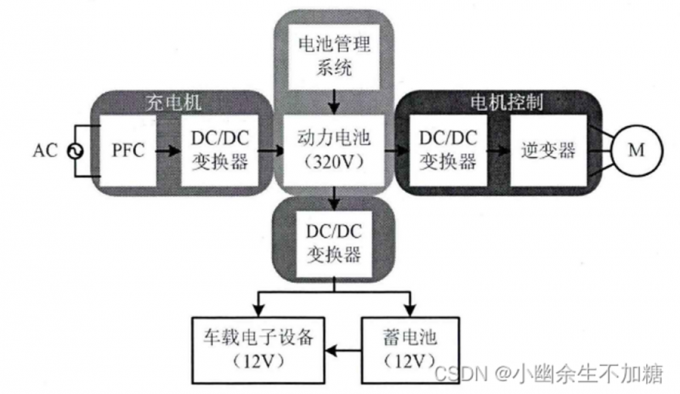

AC/DC bidirectional converter: An Innovation in test technology

In recent years, the application of AC/DC bidirectional converters in battery testing represents an important technological breakthrough. This technology can achieve:

• Charging process: Convert AC power to DC power to charge the battery

• Discharge process: Convert the DC electrical energy of the battery into AC electrical energy

• Energy recovery: Feed the energy generated by discharge back to the power grid to improve energy utilization efficiency

In traditional battery testing systems, the discharge energy is usually dissipated as heat, and the system efficiency is 0%. By using a bidirectional AC-DC converter, the dissipated energy can be returned to the system, achieving the recycling of battery test charging energy and significantly improving the system efficiency [24].

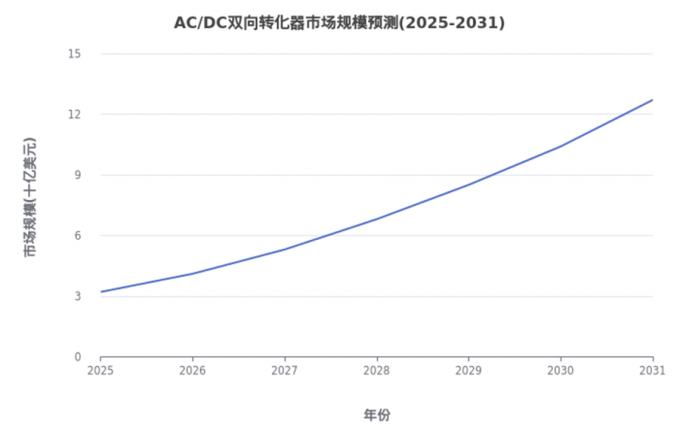

Market prospects and development trends

AC/DC bidirectional converters have broad development prospects in the battery testing market and are expected to maintain stable growth from 2025 to 2031.

Battery testing technology will develop in the following directions in the future:

The intelligence and automation levels of testing technology are constantly improving

2. Testing technology is developing towards high precision, high efficiency and low cost

3. The testing technology is closely integrated with the battery manufacturing process to achieve real-time monitoring and quality control during the production process

4. Develop new battery testing technologies to meet the development needs of new types of batteries such as solid-state batteries and lithium-sulfur batteries [8]

With the continuous innovation of battery technology, testing techniques will also keep evolving, from simple capacity testing and discharge testing to complex thermal management and safety assessment, providing strong support for the healthy development of the battery industry.

The latest progress in battery testing technology

In 2024, battery testing technology is showing a development trend of intelligence, efficiency and standardization, and multiple innovative technologies are reshaping the field of battery testing.

Applications of artificial intelligence and machine learning

Significant progress has been made in the application of artificial intelligence technology in battery testing. Machine learning algorithms perform exceptionally well in battery cycle life prediction, especially the random forest regresder, which can achieve an average absolute percentage error of at least 9.8%. These algorithms can effectively understand the trends of the data set and provide a reliable basis for battery performance evaluation [4].

Progress in electrochemical impedance spectroscopy analysis technology

In 2024, the application of electrochemical impedance spectroscopy (EIS) analysis technology in battery testing will be more widespread. This technology, by measuring the internal resistance of the battery, can evaluate parameters such as the charging and discharging efficiency and heat generation of the battery, providing an important basis for battery performance assessment [8].

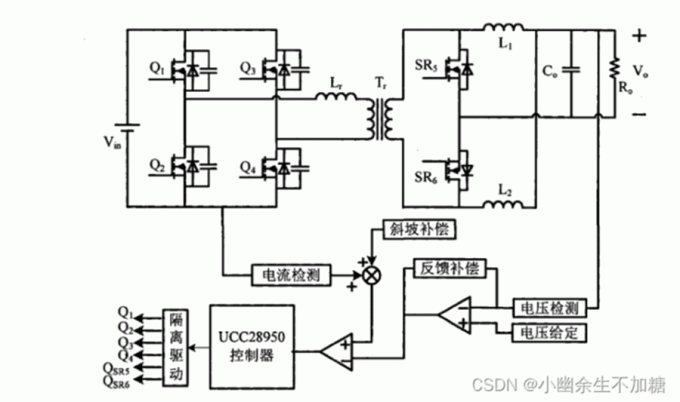

Technological innovation of AC/DC bidirectional converter

The application of AC/DC bidirectional converters in the field of battery testing is an important technological breakthrough in 2024. This technology can achieve the bidirectional flow of energy during the battery testing process, significantly improving the energy utilization efficiency of the testing system.

In traditional battery testing systems, the discharge energy is usually dissipated as heat, and the system efficiency is 0%. By using a bidirectional AC-DC converter, the dissipated energy can be returned to the system, achieving the recycling of battery test charging energy. Experiments show that the converter adopting this technology has an efficiency as high as 92.9% at a 300W input (for battery charging) and 93.6% at a 1500W output (supporting the busbar) [21].

The improvement of standardized testing methods

In 2024, the battery testing standard system will be more complete, and international standards will gradually align with domestic ones. The main standards include IEC62660 series, ISO12405 series and GB/T31484-2015, etc. These standards cover multiple aspects such as battery capacity testing, cycle life testing and safety testing [13].

Breakthroughs in battery technology for new energy vehicles

In 2024, major breakthroughs were made in battery technology for new energy vehicles, especially in terms of energy density, charging speed and cycle life. The energy density of batteries has significantly increased. For instance, the energy density of Tesla's 4680 battery has reached as high as 300Wh/kg, and that of CATL's Qilin battery has reached 304Wh/kg. The charging speed has also achieved a qualitative leap. The 800V high-voltage platform technology enables the charging power to reach 500kW, significantly reducing the charging time [11].

The market for battery formation and testing is growing

The global market size for battery formation and testing of electric vehicles was approximately 1,341.2 million US dollars in 2023. It is projected to grow at a compound annual rate of 17.5% over the next six years and reach 5,865.8 million US dollars by 2030. The market growth is mainly driven by the increasing demand for fast charging functions to reduce charging time and enhance the convenience of electric vehicles [12].

In conclusion, in 2024, battery testing technology will show a development trend of intelligence, efficiency and standardization. The application of AC/DC bidirectional converter technology, the introduction of artificial intelligence algorithms and the improvement of the standard system have jointly promoted the rapid development of battery testing technology, providing strong support for the healthy development of the battery industry.

Comparison of battery testing technology standard systems at home and abroad

Battery testing standards are an important guarantee for ensuring battery performance, safety and reliability. With the rapid development of the global electric vehicle and energy storage markets, the battery testing standard systems at home and abroad are also constantly improving. This article will analyze the differences between domestic and foreign battery testing technology standard systems.

International Battery testing standard system

International battery testing standards are mainly formulated by the International Electrotechnical Commission (IEC), the International Organization for Standardization (ISO), Underwriters Laboratories (UL), the Society of Automotive Engineers (SAE), and relevant institutions in the European Union [13].

The standards for power lithium-ion batteries issued by IEC mainly include IEC62660-1:2010 "Lithium-ion Power Battery cells for Electric Road vehicles - Part 1: Performance testing" and IEC62660-2:2010 "Lithium-ion Power Battery cells for Electric Road Vehicles - Part 2: Reliability and abuse testing". These standards mainly target the performance and safety tests of individual battery cells [13].

The standards formulated by ISO include the ISO12405 series, which is divided into three parts: ISO12405-1 for high-power batteries, ISO12405-2 for high-energy batteries, and ISO12405-3 for safety performance requirements. The aim is to provide vehicle manufacturers with optional test items and methods [13].

The UL2580 standard of the United States mainly assesses the reliability of battery abuse and the ability to protect personnel when abuse causes harm. The SAE standard system is more complete, including SAEJ2464 for battery abuse testing, SAEJ2929 for battery system safety standards, and SAEJ2380 for battery vibration testing, etc. [13]

Chinese battery testing standard system

The battery testing standard system in China started relatively late but has developed rapidly. In 2001, the Automotive Standardization Committee issued China's first guiding technical document for the testing of lithium-ion batteries in electric vehicles, GB/Z18333.1:2011 "Lithium-ion Batteries for Electric Road Vehicles" [13].

In 2006, the Ministry of Industry and Information Technology issued QC/T743 "Lithium-ion Power Batteries for Electric Vehicles", which was revised in 2012. These early standards were mainly targeted at the monomer and module levels and had a relatively narrow application scope [13].

In 2015, the Standardization Administration of the People's Republic of China promulgated a series of standards. Including GB/T31484-2015 "Cycle Life Requirements and Test Methods for Power Batteries for Electric Vehicles", GB/T31485-2015 "Safety Requirements and Test Methods for Power Batteries for Electric Vehicles", GB/T31486-2015 "Electrical Performance Requirements and Test Methods for Power Batteries for Electric Vehicles", and GB/T31 467 series standards [13].

The main differences between domestic and foreign standard systems

1. Completeness of the standard system: The international standard system is more complete, covering all aspects of batteries, while the Chinese standard system, although developing rapidly, is still being continuously improved [14].

2. Focus of test methods: International standards place more emphasis on the safety and reliability testing of batteries, such as UL and SAE standards; The Chinese standard, on the other hand, pays more attention to the performance and cycle life tests of batteries [13].

3. Standard update frequency: International standards are updated frequently to adapt to the rapidly developing battery technology. The update of Chinese standards is relatively slow, but the update speed has accelerated in recent years [14].

4. Strictness of test conditions: In some test items, the test conditions of Chinese standards may be more stringent to adapt to the special climate and road conditions in China [13].

5. Degree of internationalization of standards: China is actively promoting the internationalization of battery testing standards, facilitating the alignment of domestic standards with international ones, and enhancing the international competitiveness of Chinese battery products [14].

With the continuous development of battery technology and the expansion of application scenarios, the battery testing standard system will also be constantly improved. The differences between domestic and foreign standards will gradually narrow, jointly promoting the healthy development of the global battery industry.

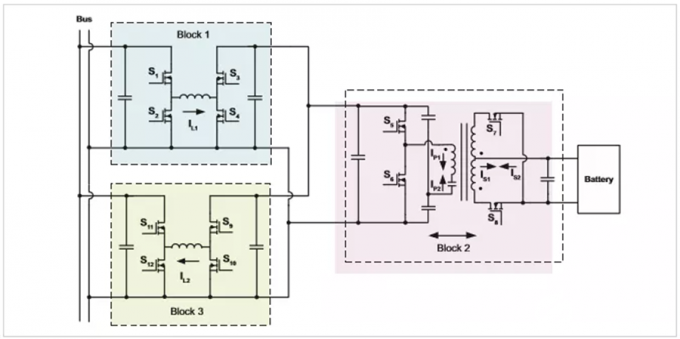

The Application of AC/DC Bidirectional Converter in Battery Testing

AC/DC bidirectional converters have broad application prospects in the field of battery testing, and their bidirectional energy flow characteristics have brought revolutionary changes to battery testing.

Energy recovery type battery testing system

In traditional battery testing systems, the energy during battery discharge is usually dissipated as heat, and the system efficiency is 0%. The test system using a bidirectional AC/DC converter can achieve the recycling of energy:

• Charging stage: Convert AC grid power into DC power to charge the battery

• Discharge stage: Convert the DC power of the battery back to AC power and feed it back to the power grid

The energy recovery rate is as high as over 90%, significantly reducing the energy consumption for testing [21].

This energy recovery type testing system is particularly suitable for the testing process of large-scale battery production lines and can significantly reduce operating costs.

Battery cycle life test

Bidirectional AC/DC converters play a significant role in battery cycle life tests:

Achieve precisely controlled charge and discharge cycles to simulate actual usage scenarios

Support high-precision current and voltage control to ensure consistency in test conditions

• It can perform complex charge and discharge curves to evaluate battery performance under different working conditions [8]

Battery Backup System (BBU) test

The bidirectional AC/DC converter can be used as the interface of the battery backup system for testing and verification:

Simulate power grid failure scenarios to test the battery pack's ability to maintain equipment functions

Monitor the voltage drop of the battery pack during discharge and verify the ability of the power conversion interface to maintain the bus voltage

Realize battery charging and busbar interface functions in a single device to gain cost and size advantages [21]

Electric vehicle battery testing

In the field of electric vehicle battery testing, bidirectional AC/DC converters have unique advantages:

Simulate the charging and discharging conditions of vehicles, including fast charging and slow charging scenarios

• Test the battery performance under an 800V high-voltage platform. For instance, the charging power of the ZEEKR 007 can reach 500kW under an 800V high-voltage platform [11]

Evaluate the performance of the battery under different temperature and load conditions

High-efficiency testing platform

The newly developed bidirectional AC/DC converter test platform has significant efficiency advantages:

When charging the battery, the efficiency can reach up to 92.9%(300W).

The efficiency reaches 93.6%(1500W) when supporting the busbar.

Higher power levels can be easily achieved through reconfiguration or parallel connection [21].

Test of energy storage system

In the testing of energy storage systems, the three-port bidirectional AC/DC converter provides a flexible testing solution:

It provides three interfaces: DC-BUS port, DC input port and AC port

Support the situation where the battery voltage is lower than the peak amplitude of the AC voltage

• Conduct bidirectional energy exchange tests between energy storage systems and power grids [6]

The application of bidirectional AC/DC converter technology not only enhances the efficiency and accuracy of battery testing, but also reduces the testing cost, providing strong support for the rapid development of battery technology. With the continuous innovation of battery technology, the application of bidirectional AC/DC converters in the field of battery testing will become more widespread.

Advantages of the bidirectional AC/DC converter battery testing system

Bidirectional converter technology has brought about a revolutionary change in the field of battery testing, significantly enhancing the efficiency and performance of the testing system through innovative energy management methods. This article conducts an in-depth analysis of the core advantages of this technology and its impact on the battery testing industry.

Energy recovery and system efficiency improvement

The main defect of the traditional battery testing system lies in the low energy utilization rate. During the discharge test process, the energy released by the battery is usually converted into heat dissipation, and the energy utilization efficiency of the system is close to zero. The test system adopting bidirectional converters has completely changed this situation:

• Energy recycling: The energy generated by battery discharge is fed back to the power grid or other test units

• Significantly reduce energy consumption: The energy recovery rate can reach over 90%, greatly reducing energy consumption during the testing process

• Reduce heat dissipation requirements: Minimize heat generation and simplify the design of the cooling system

This highly efficient energy management approach is particularly suitable for large-scale battery production lines, which can significantly reduce the operating costs and carbon emissions in the testing process.

The qualitative change in test accuracy and control capability

Bidirectional converter technology has brought unprecedented precision and control capabilities to battery testing:

• High-precision current control: Achieve milliampere-level precise current regulation to meet the testing requirements of various batteries

• Dynamic response capability: Quickly adjust charging and discharging parameters to simulate load changes in actual usage scenarios

• Complex working condition simulation: Capable of executing multiple charge and discharge curves to evaluate the performance of the battery in different application scenarios

These advantages make the test results more reliable and provide a solid foundation for battery performance evaluation and quality control.

Multi-functional integration and space efficiency

Modern bidirectional converter test systems have achieved multi-functional integration, bringing significant space and cost advantages:

• Function integration: Achieve battery charging and discharging functions in a single device to reduce the number of devices

• Modular design: Power levels can be easily expanded through parallel connection or reconfiguration, enhancing system flexibility

• Reduced floor space: The integrated design reduces the space requirements of the testing system and optimizes the layout of laboratories or production lines

The ability to adapt to new battery technologies

With the rapid development of battery technology, the test system must have the ability to adapt to new types of batteries:

• High-voltage platform support: Adapt to the testing requirements of 800V high-voltage battery platforms and meet the development requirements of fast charging technology for new energy vehicles

• Wide voltage range: Supports various battery tests from low voltage to high voltage, adapting to the development of different battery technologies

• Programmability: Adapt to the testing requirements of new types of batteries through software updates to extend the service life of testing equipment

Standardized tests are in line with international standards

The bidirectional converter test system helps to achieve the standardization of battery testing:

• Comply with international standards: Supports the testing methods stipulated in international standards such as IEC62660 series and ISO12405 series

• Test consistency: Ensure that the test results of batteries from different batches and different manufacturers are comparable

• Promote international cooperation: Facilitate the alignment of domestic battery testing standards with international standards to enhance the international competitiveness of Chinese battery products.

Cost-benefit analysis

The economic benefits of the bidirectional converter test system are mainly reflected in the following aspects:

|

成本因素 |

传统测试系统 |

双向转换器测试系统 |

|---|---|---|

| 能源消耗 | 高(能量完全损耗) | 低(能量回收率>90%) |

| 设备投资 | 中等 | 较高(但长期回报显著) |

| 运营成本 | 高(高能耗、高散热) | 低(能量循环利用) |

| 空间需求 | 大(多设备) | 小(集成化设计) |

| 系统扩展性 | 有限 | 高(模块化设计) |

With the continuous innovation of battery technology and the increasing complexity of testing requirements, bidirectional converter technology will play an increasingly important role in the field of battery testing, promoting the battery industry to develop in a more efficient, safer and more sustainable direction.

Market size and growth forecast

The battery testing market is experiencing rapid growth, especially as the application of bidirectional converter technology has driven industry transformation. The global market size for battery formation and testing of electric vehicles was approximately 1,341.2 million US dollars in 2023. It is projected to grow at a compound annual rate of 17.5% over the next six years and reach 5,865.8 million US dollars by 2030 [12]. This growth was mainly driven by the increasing demand for fast charging functions and the rapid development of the electric vehicle industry.

Technological innovation and expansion of application scenarios

In the future, bidirectional converter technology will present the following development trends in the field of battery testing:

1. Popularization of energy recovery technology: The bidirectional converter technology will completely change the situation in traditional test systems where energy is dissipated as heat. By feeding energy back to the power grid, it can achieve an energy recovery rate of over 90%, significantly reducing test energy consumption and operating costs [21].

2. Increased demand for high-voltage platform testing: With the development of 800V high-voltage platform technology, battery testing equipment needs to adapt to the testing requirements of higher voltage and greater power. For instance, under an 800V high-voltage platform, the charging power of the ZEEKR 007 can reach 500kW, and it only takes 10 minutes to charge from 30% to 80%[11].

3. Multi-scenario application expansion: Bidirectional converter technology will be widely applied in various scenarios:

- Electric vehicle battery testing: Simulate actual charging and discharging conditions to evaluate battery performance under high-voltage platforms

-Energy storage system testing: Achieve bidirectional energy exchange testing between the energy storage system and the power grid

- Battery backup system testing: Implement battery charging and busbar interface functions in a single device to gain cost and size advantages.

The global bidirectional converter battery testing market will show a regional differentiated development trend:

1. Asia-pacific region: The Asia-Pacific region, represented by China, will become the largest market growth point, mainly due to the rapid development of the electric vehicle industry in this region and government policy support.

2. European market: The European market will place greater emphasis on the improvement of testing standards and environmental protection requirements, promoting the wide application of energy recovery type testing systems.

3. North American market: The North American market will pay more attention to high-end testing equipment and intelligent solutions, promoting the integration of artificial intelligence and testing technology.

Changes in the market competition pattern

With the development of technology, the competitive landscape of the bidirectional converter battery testing market will undergo significant changes:

1. Increased technical barriers: As testing technologies become more complex and specialized, market entry barriers will rise, and leading manufacturers will take the lead by relying on advanced technologies and complete supply chains [17].

2. Accelerated industry consolidation: It is expected that within the next few years, the industry will undergo a round of consolidation, forming industrial clusters centered on technology-leading enterprises.

3. Deepening of specialized division of labor: The market will form a more specialized division of labor, with some enterprises focusing on the development of test solutions for specific application scenarios.

Integration of intelligence and data analysis

The future bidirectional converter test system will be more intelligent:

1. Artificial intelligence application: Integrating artificial intelligence algorithms for battery state estimation and life prediction, for instance, the random forest regressive device can achieve an average absolute percentage error of at least 9.8% [4].

2. Big data analysis: By collecting and analyzing massive amounts of test data, the accuracy and efficiency of testing are enhanced, providing data support for battery design and manufacturing.

3. Modular and scalable design: Power levels can be easily expanded through parallel connection or reconfiguration, enhancing system flexibility and adapting to the development needs of different battery technologies [21].

With the continuous innovation of battery technology and the increasing complexity of testing requirements, bidirectional converter technology will play an increasingly important role in the field of battery testing, promoting the battery industry to develop in a more efficient, safer and more sustainable direction.

Innovation in energy recovery technology

In 2024, AC/DC bidirectional converters made a breakthrough in the field of battery testing. In traditional battery testing systems, the energy during battery discharge is usually dissipated as heat, and the system efficiency is close to 0%. The test system adopting bidirectional converters has completely changed this situation and achieved efficient recycling of energy [10].

The newly developed bidirectional AC/DC converter test platform demonstrates significant efficiency advantages:

When charging the battery, the efficiency can reach up to 92.9%(300W).

The efficiency reaches 93.6%(1500W) when supporting the busbar.

The energy recovery rate exceeds 90%, significantly reducing the energy consumption for testing [21].

Multi-functional integration and application scenario expansion

The bidirectional converter test system in 2024 has achieved multi-functional integration, enabling both battery charging and discharging functions in a single device, significantly reducing the number of devices and floor space. This integrated design is particularly suitable for:

Battery cycle life test: Achieve precisely controlled charge and discharge cycles to simulate actual usage scenarios

2. Battery Backup System (BBU) Test: Simulate a power grid failure scenario to test the battery pack's ability to maintain equipment functionality

3. Electric vehicle battery testing: Supports 800V high-voltage platform testing, meeting the development needs of fast charging technology for new energy vehicles

4. Energy storage system testing: Three interfaces, namely DC-BUS port, DC input port and AC port, are provided to realize the bidirectional energy exchange test between the energy storage system and the power grid [8].

Integration of intelligence and data analysis

In 2024, the bidirectional converter test system will be deeply integrated with artificial intelligence technology, bringing about significant improvements in test accuracy and efficiency:

Machine learning algorithms perform exceptionally well in battery cycle life prediction, especially the random forest regresder, which can achieve an average absolute percentage error of at least 9.8%

Big data analysis technology is used to collect and analyze massive amounts of test data, providing data support for battery design and manufacturing

The intelligence and automation levels of testing technology are constantly improving, and technologies such as artificial intelligence and big data are utilized for battery performance prediction and life assessment [9].

The battery testing market is experiencing rapid growth, especially as the application of bidirectional converter technology has driven industry transformation. The global market size for battery formation and testing of electric vehicles was approximately 1,341.2 million US dollars in 2023. It is projected to grow at a compound annual rate of 17.5% over the next six years and reach 5,865.8 million US dollars by 2030. This growth was mainly driven by the increasing demand for fast charging functions and the rapid development of the electric vehicle industry [12].

Standardization is in line with international standards

In 2024, the battery testing standard system will be more complete, and international standards will gradually align with domestic ones. The main standards include IEC62660 series, ISO12405 series and GB/T31484-2015, etc. These standards cover multiple aspects such as battery capacity testing, cycle life testing and safety testing, providing normative guidance for the application of bidirectional converter testing systems [13].

With the continuous innovation of battery technology and the increasing complexity of testing requirements, bidirectional converter technology will play an increasingly important role in the field of battery testing, promoting the battery industry to develop in a more efficient, safer and more sustainable direction.

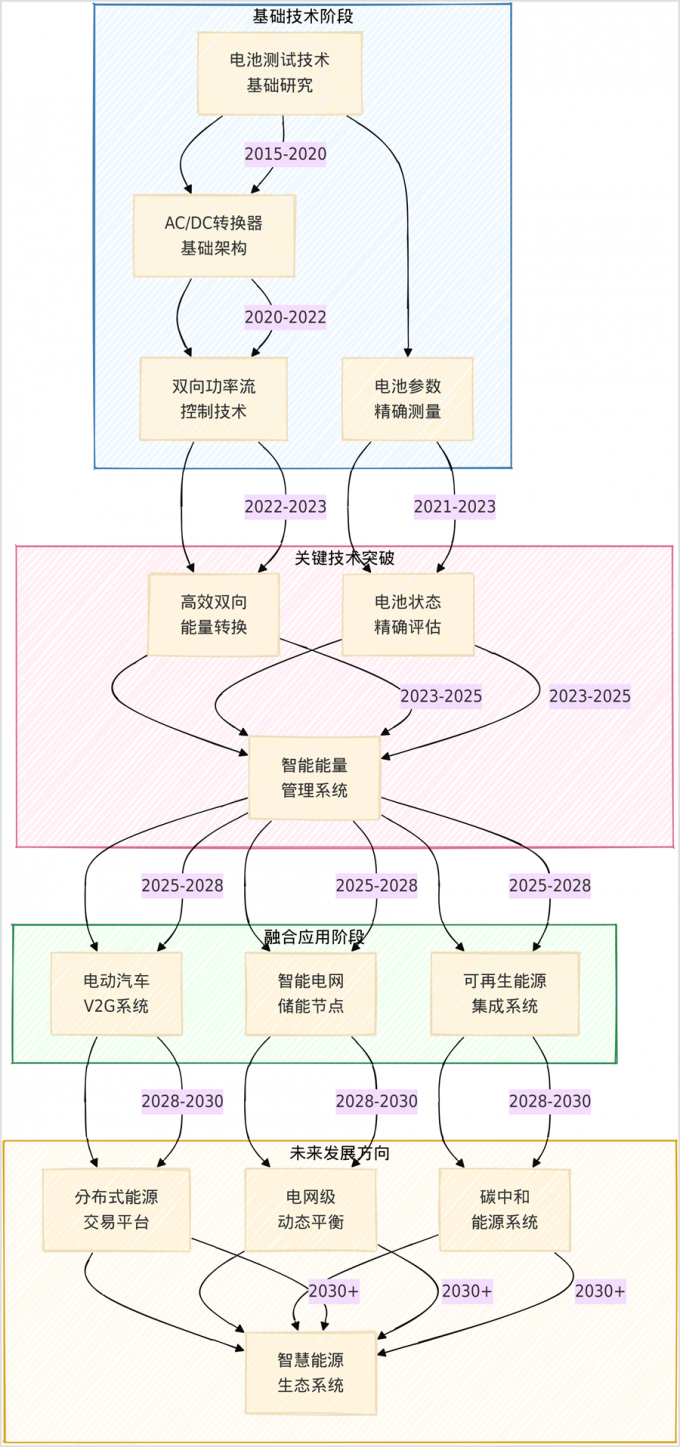

A roadmap for the integrated development of battery testing technology and AC/DC bidirectional converter technology

The key node of technological integration

The emergence of energy recovery type testing systems (2020-2022)

In traditional battery testing systems, the discharge energy is usually dissipated as heat, and the system efficiency is 0%

The application of bidirectional AC-DC converters enables the dissipated energy to be returned to the system, achieving the recycling of battery test charging energy

The energy recovery rate reaches over 90%, significantly reducing test energy consumption and operating costs [24]

2. Breakthroughs in High-Efficiency Bidirectional Converter Technology (2023-2024)

The efficiency of the newly developed bidirectional AC/DC converter test platform has been significantly improved:

When charging the battery, the efficiency can reach up to 92.9%(300W).

The efficiency reaches 93.6%(1500W) when supporting the busbar.

Higher power levels can be easily achieved through reconfiguration or parallel connection [24].

3. Integration of Intelligent Testing Technology and Bidirectional Converters (2024-2025)

Artificial intelligence and big data technologies are applied to battery performance prediction and life assessment

Machine learning algorithms perform exceptionally well in battery cycle life prediction, with random forest regressors capable of achieving an average absolute percentage error of at least 9.8%

Testing technology is developing towards high precision, high efficiency and low cost to meet the demands of large-scale battery production [8].

1. Comprehensive standardization in line with international standards (2025-2026)

Establish and improve the battery testing standard system to enhance the accuracy and comparability of test results

Promote the alignment of international standards with domestic ones and facilitate the international development of battery testing technology

The main standards include IEC62660 series, ISO12405 series and GB/T31484-2015, etc. [13]

2. Multi-functional Integration and Application Scenario Expansion (2026-2027)

Achieve battery charging and busbar interface functions in a single device to gain cost and size advantages

The application has expanded to multiple fields such as electric vehicles, energy storage systems, and portable electronic devices

• Supports 800V high-voltage platform testing to meet the development needs of fast charging technology for new energy vehicles [9]

3. Adaptation of New Battery Testing Technologies (2027-2028)

Develop testing technologies applicable to new types of batteries such as solid-state batteries and lithium-sulfur batteries

Explore non-destructive testing technology, micro-nano testing technology, etc., to enhance testing accuracy and efficiency

Strengthen the integration of battery testing with battery design, manufacturing, recycling and other links to achieve full life cycle testing [8]

4. Deep Integration of Intelligence and Automation (2028-2030)

The intelligence and automation levels of testing technology are constantly improving

• Utilize technologies such as artificial intelligence and big data to predict battery performance and assess battery life

Testing technology emphasizes a close integration with battery manufacturing processes to achieve real-time monitoring and quality control during the production process [9]

Market prospect

The global market size for battery formation and testing of electric vehicles is expected to grow from 1,341.2 million US dollars in 2023 to 5,865.8 million US dollars in 2030, with a compound annual growth rate of 17.5%. This growth was mainly driven by the increasing demand for fast charging functions and the rapid development of the electric vehicle industry [12].

With the continuous innovation of battery technology and the increasing complexity of testing requirements, bidirectional converter technology will play an increasingly important role in the field of battery testing, promoting the battery industry to develop in a more efficient, safer and more sustainable direction.

-

2025-11-13

-

2025-11-11

-

2025-11-09

-

2025-11-07